High-Temperature ⍺ – Amylase

- Home

- Products & Applications

- High-Temperature ⍺ – Amylase

High-Temperature ⍺ - Amylase

Description:

This is a bacterial amylase that derives from Bacillus licheniformis. Because of its tolerance for high temperatures, it is widely used in the production of starch sugars such as: glucose, fructose, maltose and dextrin. It is also used in the manufacturing of monosodium glutamate, organic acids, and gluconic acid salts.

Technical information:

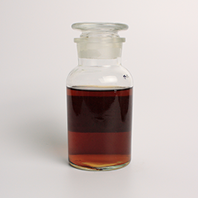

- Available in liquid (brown) 20,000; 30,000; 40,000 u/ml. based on starch as substrate.

- Effective temperature : 55-100℃ (Optimum temperature: 80-97℃).

- On steam injection liquefaction, the momentary temperature can be up to 105-112℃

- pH range: 4.3-8.0 (Optimum pH: 5.2-6.0 )

Mode of Action:

This is an endo-enzyme that will randomly hydrolyzes α-1,4 glucosidic linkages of gelatinized starch

Into soluble dextrins, thus reducing high viscosity of the starch slurry.

Uses:

- Starch as raw material

Slurry density: 10-20 Bé scale; pH: 5.6-5.8; steam injection temperature: 108-110℃; laminar flow: 90 minutes; make DE value 5-20% liquefied solution.

Recommended dosage: 150-500 ml/ton on dry basis, based on 40,000 u/ml.

- Dry smash starch as raw material

Slurry density: 10-20 Bé scale; pH 5.8-6.2; injection temperature: 95-110℃; laminar flow: 90 minutes; make DE value 5-20% liquefied solution.

Recommended dosage: 600-900 ml/ton on dry basis, based on 40,000 u/ml.

- Other applications

High-Temperature α-Amylase shows excellent low pH properties in alcohol and brewery manufacturing, textile, dye, and printing fermentation industries. The lowest pH value up to 4.6, especially, in the alcohol industry. The dosage refers to the introduction of high temperature α-amylase.

Packaging, Storage & Handling

- Liquid: Plastic drums of 22; 200; 840 and 1,000 L.

- Powder: 20 kg cartons; 25 kg bags and 25 kg drums.

- Storage & handling: Avoid exposure to direct sunlight; keep in clean, cool, and dry place