Glucoamylase

- Home

- Products & Applications

- Glucoamylase

Glucoamylase

Description:

This enzyme is obtained by controlled fermentation of Aspergillus niger, and it is widely used in the brewing industry, manufacturing of starch sugars, alcohol monosodium glutamate and antibiotics

Technical information:

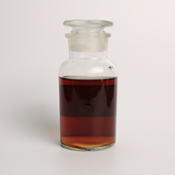

- Available in liquid (brown) 100,000; 150,000; 200,000 and 300,000 u/ml. In powder form: 100,000 u/ml.

- Temperature range: 40-70℃ (Optimum temperature: 60—65℃).

- pH range: 3.0-5.5 (Optimum pH: 4.2-4.6)

- Unit definition: The amount of enzyme needed to liberate 1 mg of starch in one hour at a pH of 4.6 at 40℃

Mode of Action:

Glucoamylase will hydrolyze terminal 1,4 linked α-D-glucose residues successively from non-reducing ends of amylose chains to release free glucose. This fermentation also can hydrolyze α 1, 6 glucosidic linkages into isomaltose and dextrins.

Uses:

- Alcohol

Due to its high debranching activity and its ability to digest starch, glucoamylase can be used for alcohol production.

Recommended dosage: 1.0 to 1.6 L/ton of raw marl at 60 to 65℃.

- Starch sugar

Recommended dosage: 1.0 to 3.0 L/ton of raw material.

- Dry beer

Recommended dosage: 0.2 to 0.5 L/ton of dry malt.

- Liquor brewing and vinegar

Recommended dosage: 1.0 to 1.5 L/ton of raw material.

- Monosodium glutamate, antibiotics, and citric acid

Recommended dosage: 1.0 to 3.0 L/ton of raw material

Packaging, Storage & Handling

- Liquid: Plastic drums of 22; 200; 840 and 1,000 L.

- Powder: 20 kg cartons; 25 kg bags and 25 kg drums.

- Storage & handling: Avoid exposure to direct sunlight; keep in clean, cool, and dry place.