ß- Glucanase

- Home

- Products & Applications

- ß- Glucanase

ß - Glucanase

Description:

It is an enzyme obtained through submerged fermentation of Trichoderma reesei and recovered by Modern Back Extraction Technique. Commonly used in the manufacturing of beer, feed, paper production and as an antifungal compound in plants.

Technical information:

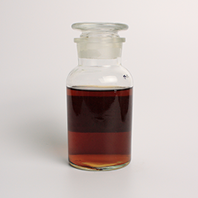

- Available in liquid form (brown; 20,000 u/ml.) or in powder form (white; 30,000 u/gr). Food grade quality 90,000 u/ml.

- Temperature range: 30 to 70℃ (Optimum temperature: 50-60℃). Higher activity can be obtained at 60 to 70℃ for 30 min.

- pH range: 3.5-5.5 (Optimum pH: 4.8-5.5)

- Unit definition: One unit (U) of β-glucanase activity is defined as the amount of enzyme which liberates 1 μmol reducing sugar per min at 50℃ and a of pH 5.5 (Standard: LDZJ03. 03-2010)

Mode of Action:

The main function of glucanase is to break down large polysaccharides (glycosidic bonds) via hydrolysis to diminish its hydrophilic activity and viscosity in the substrate.

Uses:

- Beer

Glucanase breaks down the β-glucans located in the cell walls of the endosperm of the barley, this is important because glucans can be a problem during wort production and beer filtration. Glucanase should be added at the beginning of the saccharification stage. Glucanase can have an effect in the color, texture, clarification, and flavor of the beer.

Recommended dosage: 0.5 to 0.25 L/ton of malt based on 20,000 u/ml. - Feed

Poultry: In diets rich in barley, β-glucanase improves the digestibility of the ingesta thus increasing weight gain and improving feed conversion.

Recommended dosage: 0.02 to 0.1 kg/ton based on 20,000 u/ml.

Packaging, Storage & Handling

- Packaging. Liquid: Plastic drums of 22; 200; 840 and 1,000 L..

- Powder: 20 kg cartons; 25 kg bags and 25 kg drums.

- Storage & handling: Due to its organic nature, high temperature, strong acid & strong alkaline conditions will inactivate the enzyme.

- Avoid exposure to sunlight, keep in clean, cool, and dry place